Tolerance analysis is a name given to a number of approaches used today in product design to understand how imperfections in parts as they are manufactured, and in products as they are assembled, affect the capability of a product to meet customer expectations. Tolerance analysis is a way of understanding how sources of variation in part dimensions and assembly constraints propagate across parts and assemblies, and how that total variation affects the capability of a design to achieve its design requirements within the process capabilities of manufacturing organizations and supply chains.

Tolerancing directly influences the cost and performance of products. For example, in electrical devices, safety requires that the power supply be located a certain minimum distance from adjacent components, such as another sheet-metal part, in order to eliminate electrical short circuits across that distance. Tolerance analysis will show whether the nominal clearances the engineer specifies will meet or violate the safety requirement, given manufacturing and assembly variability impact on the minimum clearance.

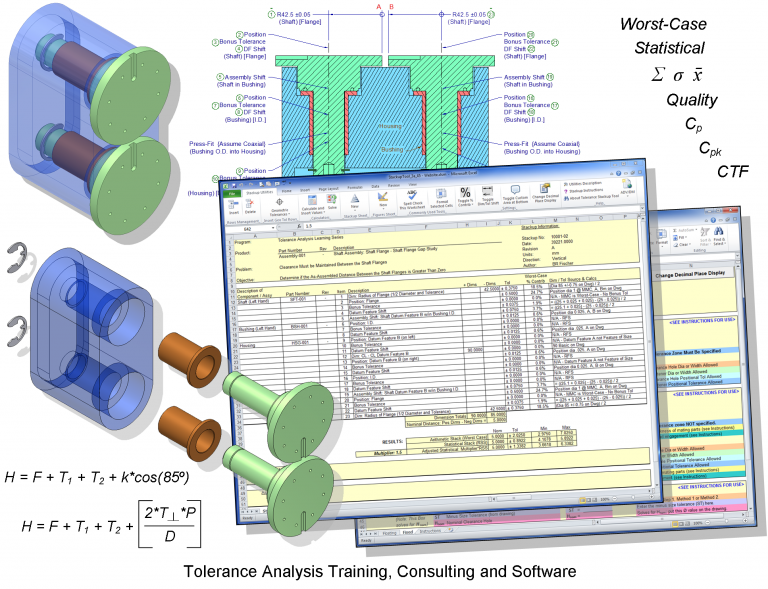

With shorter product lifecycles, faster time to market, and tighter cost pressures, the characteristics that differentiate a product from its competitors are now down in the details of a design. Engineers are going to perform a statistical tolerance analysis over a tolerance stack up in order to improve cycle time and quality and to reduce costs. They are looking more closely at why they did not get the exact part and assembly dimensions they expected from manufacturing and then are attempting to optimize the tolerances on the next version of the product. Tolerance optimization during design has a positive impact on the yields coming out of manufacturing, and better yields directly affect product cost and quality. Analyzing tolerances and variations before trying to produce a product also helps engineers avoid time-consuming iterations late in the design cycle.

As their reliance on tolerance analysis increases, many industries seek to gain a competitive advantage:

– Automotive

– Aviation

– Consumer packaging

– Electronics

– Heavy Machinery

– Medical devices

– And many others…

Quality and profitability go hand-in-hand. Companies define quality in terms of production yield and reliability, which reflect the probability of defects given an overall number of units produced. When engineers perform tolerance analysis during design, they essentially are converting design intent into a statistical or probability-based design model. The model predicts the probable yield loss for the design, or the number of rejected parts per total produced that will cause a customer to be dissatisfied. Proper tolerancing can help designers pinpoint and avoid the problems that lead to rejected parts and thereby eliminate the non-value-added cost that damages profitability.